Fiberglass reinforcement and composite profile for export from the Russian Federation

We organize supplies of fiberglass reinforcement and composite profiles for export with foreign trade support

Export of composite reinforcement and profiles worldwide

Logistics of composite reinforcement from Russia

Search for transport

We work directly with carriers and shipping lines

container booking

We take care of all the hassle of booking space on a sea vessel for shipping containers

freight payments

We will pay for freight in dollars or euros. Payment execution period is 3-4 working days.

logistics to the warehouse

We will take care of all the logistics and assembly of composite reinforcement in the warehouse.

customs clearance

We will carry out official customs clearance of the export of composite profiles and fiberglass reinforcement

documentation

We will prepare a full package of accompanying documents for the export of composite materials from Russia

SUPPLY OF GLASS COMPOSITE MATERIALS

ADVANTAGES OF COMPOSITE MATERIALS

SUPPLIERS

Only verified suppliers with their own production facilities

thermal conductivity

The thermal conductivity of composite reinforcement is 100 times lower than that of steel

delivery times

Delivery on FCA, FOB and CIF terms from 7 days

control

Quality control of reinforcement and profiles at all stages of production

QUANTITY:

volumes

Transportation of large volumes of reinforcement – from 1 million meters

saving

Transportation of Large Volumes of Reinforcement – From 1 million Mathers

any cargo

We load 40-foot containers and trucks with reinforcement in 100-meter coils and rods from 8 meters

безопасность

Low risks of loss, damage, theft of goods

Advantages of composite reinforcement

1. Light weight, ensuring high transportability.

2. High corrosion and chemical resistance, allowing the use of reinforcement in aggressive environments.

3. Possibility of use in areas with seismicity of 7-10 points.

4. Environmentally friendly material.

5. Durability (service life of about 80 years).

6. Corrosion resistance.

7. Energy efficiency.

Manufacturing technology of composite reinforcement

The technology for manufacturing composite reinforcement includes the following stages:

- Preparation of materials: use of high-quality fiberglass in the form of threads or rovings.

- Impregnation with polymer resins: impregnation of fiberglass with special polymer compounds to ensure strength and resistance to impacts.

- Forming the product: pulling the fiberglass through a production machine and giving it the required shape and size.

- Heat treatment: heating the impregnated and formed glass fibre to cure the polymer binder and ensure optimum mechanical properties.

- Cutting and packaging: cutting finished materials into standard sizes and packaging products for transportation and further use.

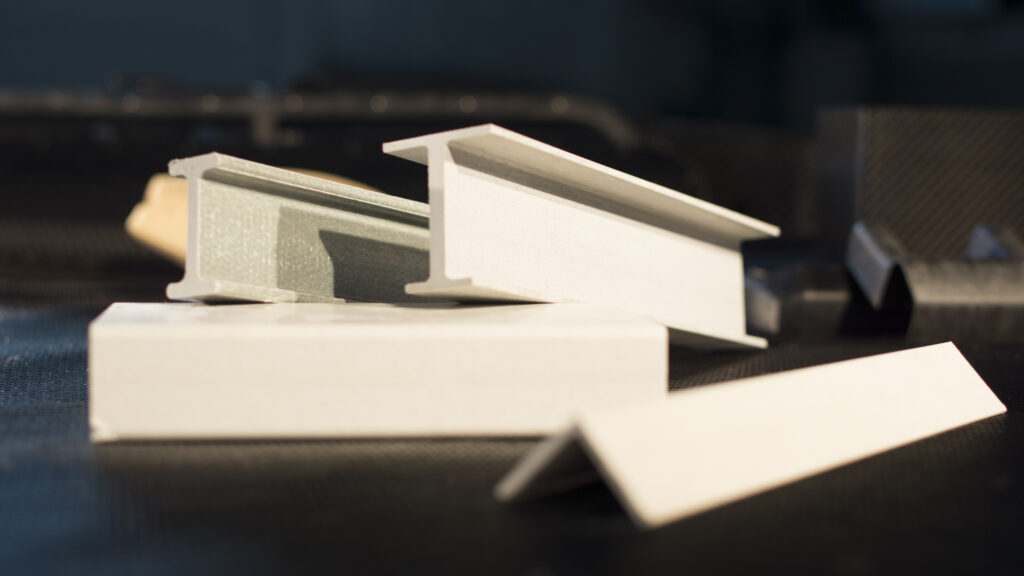

Advantages of composite profile

1. Improved physical and mechanical properties: strength close to some alloys of steel and non-ferrous metals.

2. Low weight: the specific gravity of fiberglass is 5-6 times less than that of non-ferrous and ferrous metals, and 2 times less than that of duralumin.

3. Low thermal conductivity: not inferior to wood in terms of thermal insulation, but is not subject to rotting and warping.

4. Fewer air chambers in the profiles, which simplifies the frame design.

5. No need to install reinforcing steel stiffeners.

Even more useful profile properties

6. High biological, moisture and weather resistance.

7. Unique chemical resistance to acids and alkalis.

8. Good dielectric properties.

9. Wide temperature range: from -100 °C to +180 °C.

10. High fire resistance: does not emit dioxin during combustion.

11. Low thermal coefficient of linear expansion, ensuring reliable operation of seals.

12. Long service life: 25-year warranty, does not rot, does not change color, does not scratch or form cavities.

13. A variety of shapes and a wide range of colors.

Manufacturing technology of composite profile

The technology for manufacturing a composite profile consists of the following stages:

- Cutting into panels of the required size.

- Extrusion: the polymer material enters the drying bin, then into the extruder cylinder, where the material is melted and homogenized.

- Formation of a composite panel: a homogeneous polymer mass is fed between two calenders, where it is combined with an aluminum tape and a high-molecular adhesive film.

- Rolling: The aluminum composite strip passes through rolling rollers, where the required thickness is formed and irregularities are removed.

- Thermal bonding: the aluminum strip and the polymer material are joined under the influence of temperature and pressure.

- Cooling: The cooled aluminum composite strip passes through a cooling unit and is leveled.

- Application of protective film to the outside of the product and marking to the inside.

IMPORT AND EXPORT WITH RESULT

8 YEARS OF STABLE IMPORT AND EXPORT DELIVERIES ALL OVER THE WORLD

Containers delivered

Tons of products exported

Contracts concluded

export of composite materials

We organize logistics and send composite profiles and reinforcement for export

we make the best for export

Start exporting building materials

Prospects

Integrity is the main quality for foreign economic activity, allowing the implementation of long-term projects.

instructions

We will take you by the hand to conclude a profitable foreign trade deal.

discounts

Are you with us for a long time? You can expect quality products at prices from direct manufacturers.